Automotive - DALCAN Machines-Denmark:

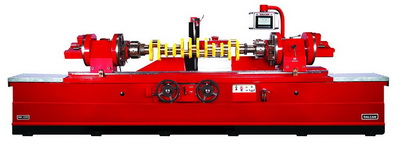

Crankshaft grinding machines DALCAN Machines-Denmark models CSG

These grinders meet the technical requirements for repairing individual crankshafts as well as small to medium-sized crankshaft series.

All models have headstocks with transverse movement and rapid rotation of 360° chucks, smooth control of the work piece rotation and a range of features.

These inexpensive machines are supplied for production based on the extensive experience of DALCAN Machines personnel in the production of precision equipment for engine restoration.

Important features of the new grinding machines are the servo motor of the grinding head, the hydraulic clamp of the tailstock center and the electronic display, which defines a new line of machines as corresponding to the best existing models of the world's most famous manufacturers.

Depending on the size of the crankshafts, you can choose one of the precise grinding machines that best suits your needs: CSG 1500, CSG 2200 or CSG 2750. You can also choose their optional equipment.

Main features of the machines:

- Heavy cast iron and aged bed - exceptional stability of the machine characteristics.

- Hydraulic table feed - quickness.

- Hydraulic clamping of the rear center - convenience.

- Hydraulic front headstock driving motor - exceptionally smooth operation and high durability.

- Easy replacement of chucks on the centers, and also installation of the centers in chucks - high productivity.

- Electronic display with parameter control - accuracy.

- Automatic table feed - the possibility of cylindrical grinding.

|

Digital Display for grinding head movement, work head speed and table speed movement

|

Strong & rigid steady rest

|

Accurate radius dressing mechanism

|

TECHNICAL SPECIFICATIONS

| PARAMETERS |

CSG 2750

|

CSG 2200

|

CSG 1500

|

| Height of centre from the table |

mm

|

350

|

300

|

265

|

| Maximum swing over table |

mm

|

700

|

600

|

530

|

| Maximum head offset |

mm

|

140

|

140

|

100

|

| Maximum distance between chuck |

mm

|

2725

|

2150

|

1450

|

| Maximum distance between centers |

mm

|

2800

|

2200

|

1500

|

| Maximum weight admitted between chuck |

kg

|

1250

|

500

|

250

|

| Diameter of self centering chucks |

mm

|

250

|

250

|

200

|

| Diameter of grinding wheel |

mm

|

813

|

813

|

710

|

| Grinding head feed per turn of handle wheel |

mm

|

1

|

1

|

1

|

| Fast grinding head feed with control |

mm

|

350

|

175

|

150

|

| Micrometeric grind head feed |

mm

|

-----

|

175

|

150

|

| Work head spindle rotation speed (variable) |

mm

|

25 - 100

|

19 - 90

|

25 -100

|

| Table slow feed per turn of hand wheel |

mm

|

5

|

5.4

|

5.4

|

| Table fast feed per turn of hand wheel |

mm / min

|

3000

|

3000

|

3000

|

| Automatic table movement |

|

-----

|

1 set

|

optional

|

| Grinding wheel spindle |

rpm.

|

760

|

760

|

900

|

| Grinding wheel motor |

kW

|

5.5 / 1440 rpm

|

5.5/ 1440 rpm

|

3.7 / 1440 rpm

|

| Work head motor |

kW

|

0.75 / 1440 rpm

|

0.37 / 1440 rpm

|

0.37 / 1440 rpm

|

| Coolant pump motor |

kW

|

0.13 / 2800 rpm

|

0.13 / 2800 rpm

|

0.13 / 2800 rpm

|

| Servo control motor (grinding wheel slide) |

kW

|

0.4

|

0.4

|

0.4

|

| Length of the machine |

mm

|

5400

|

4500

|

3500

|

| Width of the machine |

mm

|

2250

|

1750

|

1750

|

| Height of the machine |

mm

|

1650

|

1650

|

1550

|

| Work space required |

mm

|

7000 X 2000

|

5100 X 1900

|

5500 X 2000

|

| Work height required |

mm

|

1650

|

1650

|

1550

|

| Net weight |

ton

|

5

|

4

|

3.25

|

| Gross weight |

ton

|

6.5

|

4.5

|

4

|

| Shipping volume |

m3

|

17

|

17

|

15

|

STANDARD EQUIPMENT

- Self centering chuck with key

- Self centering chuck jaws

- Face and side dresser assembly

- Centers

- Steady rest

- Crank centering V gauge

- Diamond dresser

- Wheel hub

- Grinding wheel

- Ratchet spanner

- Double end spanner 24/26

- Single end spanner 46

- Allen key set ( 9 no's)

- Wheel hub puller

- Wheel balancing arbor with nut

- Leveling plate with bolt

- Foundation bolt with nut

- Coolant system

- Splash guard

- Spindle nut tightening spanner

- Lifting hole cover

- Crank truing gauge

- Crank truing dial

- Extra balancing weight with bolt

- Face plate tightening spanner

- Face plate puller

- Ball screw rod nut tightening spanner

- Radius Dresser

- Operation manual

EXTRA EQUIPMENT

- Crank polisher

- Grinding wheel 16 x 204 x 712mm

- Grinding wheel 19 x 204 x 712mm

- Grinding wheel 25 x 204 x 712mm

- Grinding wheel 19 x 204 x 812mm

- Grinding wheel 25 x 204 x 812mm

- Grinding wheel 32 x 204 x 812mm

- Wheel hub

- Normal steady rest

- Heavy duty steady rest

- Wheel balancer

- Extra balancing weight fixing bolt (set of 2)

- Crank truing gauge with dial

- Crank centering V-gauge

- Chuck (self centering)

- Chuck key

|