|

|

|

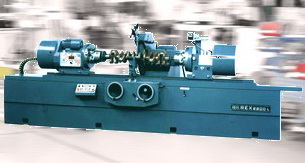

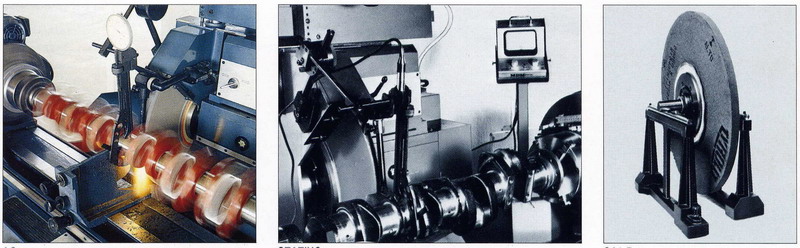

Automotive - ROBBI:

Crankshaft grinding machines models REX

ROBBI crankshaft grinding machines are backed by 80 years experience in the manufacturing of engine rebuilding equipment. Every machine is engineered to maintain exact tolerances and to be simple to use. Set-up features are designed from an operator viewpoint to be fast and simple.

.jpg)

Choose your new crankshaft grinding machine from a wide range of sizes: REX 1800, REX 2200, REX 2700. REX 3100, REX 4000, REX 6000. Each machine can be equipped with rapid hydraulic table traverse and infinitely variable hydraulic table traverse. The final choice is easy: ROBBI machines are reliable, easy to use and accurate, and that means a profitable return on investment for you.

Direct communications with the factory guarantees efficient delivery of needed spares. Coloring the machine is in any color at the customer's choice.

|

TECHNICAL FEATURES:

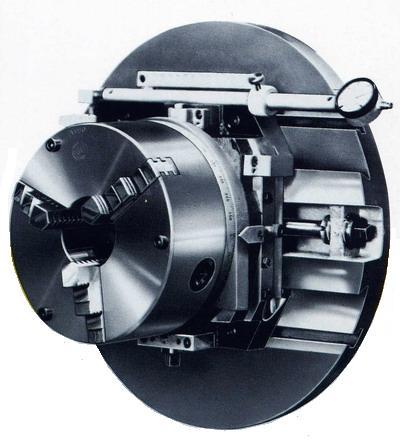

WORK HEAD

- Made up of a cast iron normalized body, stabilized and well ribbed, able to support the weight of the piece and the forces generated during the grinding operation.

- The pendulum movement allows quick and easy centering of the crankpins: moving is detected by a dial indicator.

- Zero setting is achieved by moving the heads against a center stop, which can be switched off in case of a correction in the opposite direction.

CHUCKS

- 360° Rapid rotation of the chuck

- Chuck Easy replacement

- Use of only two keys for all the operations of moving, centering and fixing

- Work head is equipped with a spindle rotating on bearings of high precision, which ensure tight tolerances and high rigidity in the working.

- The spindle rotation with three-phase motor polarity (two speeds of rotation or, on request, variable).

- The change in speed is also achieved by a transmission belt .

WHEEL HEAD

- Sideways are coaled with anti-friction material to obtain free movement and a minimum of wear.

- Hardened steel spindle turns in oil bathed fully adjustable precision sleeve bearings.

HYDRAULIC CONTROLS

- Rapid hydraulic wheel head traverse and hydraulic table movement increase speed during set up and grinding.

- Fine teed controls tor both movements assure accuracy.

VERY LARGE GUIDE

- Runs on prismatic guides with anti-friction material (turcite) reported.

- This ensures an extremely precise and smooth movement, (eliminates stic-slip), less wear of the guides and thus longer life.

- The spindle is made from hardened steel, with bearings running in an oil bath.

|

|

TECHNICAL SPECIFICATIONS

| PARAMETERS |

REX 1200 |

REX 1500 |

REX 1800 |

REX 2200 |

REX 2700 |

REX 3100 |

|

REX 6000-RS |

| Distance between centers |

mm |

1320 |

1550 |

1800 |

2300 |

2800 |

3200 |

|

6200 |

| Distance between chucks |

mm |

1300 |

1540 |

1750 |

2220 |

2700 |

3100 |

|

6050 |

| Height of centers over table |

mm |

220 |

250 |

300/350 |

300/350 |

350/400 |

400 |

|

750 |

| Swing over table |

mm |

440 |

500 |

600/700 |

600/700 |

700/800 |

800 |

|

1500 |

| Max. offset of centers |

mm |

80 |

100 |

125/150 |

130/150 |

150/200 |

200 |

|

350 |

| Max. grinding diameter |

mm |

180 |

180 |

180/200 |

180/200 |

200/230 |

230 |

|

500 |

| Fast hydraulic wheelhead traverse |

mm |

80 |

110 |

130/170 |

130/170 |

170/190 |

190 |

|

300 |

| Hand micrometric wheelhead feed |

mm |

150 |

150 |

170/200 |

180/200 |

200/220 |

220 |

|

600 |

| Hand micrometric wheelhead feed, graduation |

mm |

0,005 |

0,005 |

0,005 |

0,005 |

0,005 |

0,005 |

|

0,01-0,1 |

| Wheelhead feed per reverse |

mm |

1 |

1 |

1 |

1 |

1 |

1 |

|

3 |

| Hand micrometric worktable traverse per reverse |

mm |

11 |

11 |

8 |

8 |

8 |

8 |

|

8 |

| Fast hydraulic worktable traverse |

m/min. |

3 |

3 |

3 |

3 |

3 |

3 |

|

3 |

| Grinding wheel speeds |

rpm |

1000-1150 |

1000-1150 |

770-940 |

770-940 |

680-900 |

680-900 |

|

450-1000 |

| Max. grinding wheel diameter |

mm |

610 |

710 |

760/815 |

760/815 |

815/915 |

915 |

|

1400 |

| Min.-Max. width of grinding wheel |

мм |

19-40 |

19-50 |

19-60 |

19-60 |

19-70 |

25-70 |

|

30-70 |

| Diameter of chucks |

mm |

160 |

180 |

200/230 |

200/230 |

230/250 |

250 |

|

400 |

| Chucks holding diameter |

mm |

200 |

220 |

250/290 |

250/290 |

290/310 |

310 |

|

600 |

| Rest capacity |

mm |

30-100 |

30-100 |

30-120/160 |

30-120/160 |

30-160/200 |

30-200 |

|

400 |

| Workhead spindle speeds |

rpm |

35-70 |

20-30-40-60 |

0-60 |

0-60 |

0-60 |

0-60 |

|

0-50 |

| Max. weight on centers |

kg |

120 |

200 |

350/600 |

350/600 |

600/950 |

950 |

|

3000 |

| Max. weight on rests |

kg |

300 |

500 |

800/1500 |

800/1500 |

1500/2200 |

2200 |

|

6000 |

|

POWER |

| Wheel head motor |

kW |

3,0 |

4,1 |

7,5/10 |

7,5/10 |

10/12,5 |

12,5 |

|

30 |

| Workhead spindle motor |

kW |

0,2-0,3 |

1 |

1 |

1 |

1/2 |

2 |

|

5 (5x2) |

| Hydraulic power motor |

kW |

0,3 |

0,5 |

1,25 |

1,25 |

1,25/1,5 |

1,5 |

|

4 |

| Cooling pump motor |

kW |

0,1 |

0,1 |

0,12 |

0,12/0,25 |

0,12/0,25 |

0,25 |

|

0,25 |

|

DIMENSIONS |

| Length |

mm |

3300 |

3900 |

4500 |

5000/5500 |

5000/6000 |

6500 |

|

16500 |

| Width |

mm |

1350 |

1500 |

1650 |

1750/1850 |

1750/2100 |

2100 |

|

3500 |

| Height |

mm |

1550 |

1700 |

1700 |

1750/1800 |

1800/2000 |

2000 |

|

2700 |

| Workspace required |

mm |

4600x1500 |

5500x1650 |

6300x1800 |

7300x1800 |

8800x2200 |

9700x2200 |

|

20000x4000 |

| Approx. net weight |

kg |

2800 |

3300 |

4600/5000 |

5000/6400 |

5400/7400 |

8400 |

|

30000 |

| Approx. gross weight |

kg |

3200 |

3800 |

5200/5800 |

5800/7700 |

6200/8700 |

10000 |

|

32000 |

| Shipping box size |

m |

3x1,5x1,7 |

3,6x1,64x1,8 |

4,0x1,76x1,72 |

5,9x1,86x1,8 |

6,2x2,0x2,0 |

7,0x2,0x2,0 |

|

20x4x3 |

STANDARD EQUIPMENT

- Electric installation 24 V

- Hydraulic installation

- Cooling installation with tank

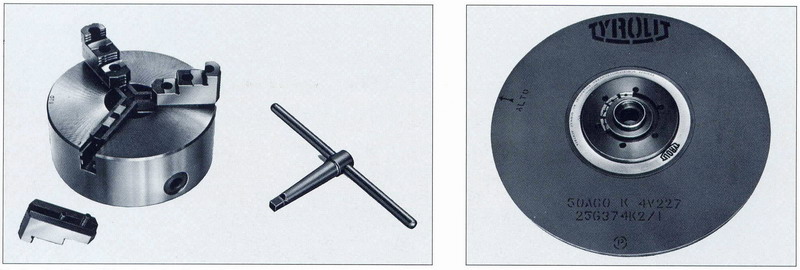

- Two self centering chucks

- Pair of additional counter weights

- Grinding wheel with pair of wheel hubs

- Narrow steady rest

- Normal steady rest

- Wheel periphery and side truing attachment with diamond

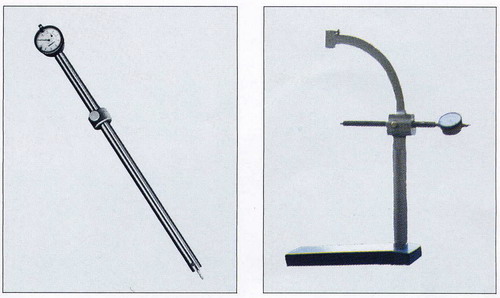

- Eccentricity control device with dial gauge

- Truing fixture for checking concentricity with dial gauge

- V-square for centering of crankpins with dial gauge

- Wheel balancing mandrel

- Motor drive pulley for reduced wheel diameter

- Grinding wheel stripper

- Set of steel splash guards

- Service spanners

- Operating manual

EXTRA EQUIPMENT - TOOLS AND DEVICES

- Complete set of centers

- Center and longer center to be mounted on the chuck

- System for gauging while working capacity from diam. 25-100 mm.

- Electronic equipment for continuous gauging during grinding work operation with one screen with automatic change hundredths-thousandths complete with transducer head applicable on AG

- Balancing stand for grinding wheels and other rotating parts, blade type, with precision level

- Portable belt super finisher

- Coolant magnet cleaner (type DMD/100) with tank and pump

- Coolant paper roll cleaner (type DTE/100) with tank and pump

- Grinding wheel recessing attachment

- Narrow steady rest

- Hydraulic truing attachment for wheel periphery, without diamond

- Infinitely variable hydraulic table traverse speed 0 to 3000 mm/min with automatic reversing and variable dwell for cylindrical grinding

- Protections mechanical and electrical in conformity with safety CE rules

- Emulsifying oil fog aspirator

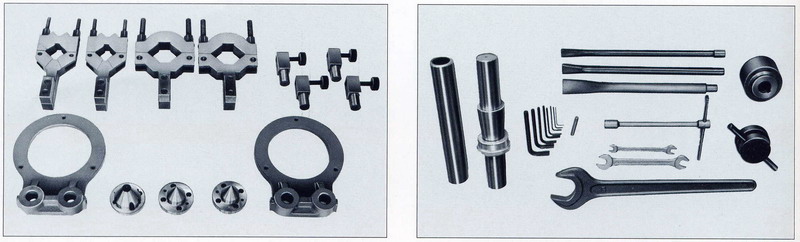

Chuck and grinding wheel

Complete set of centers, service spanners

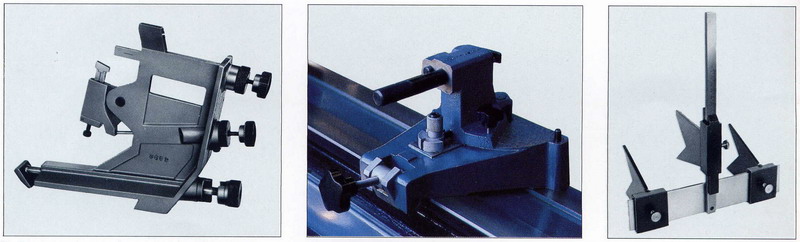

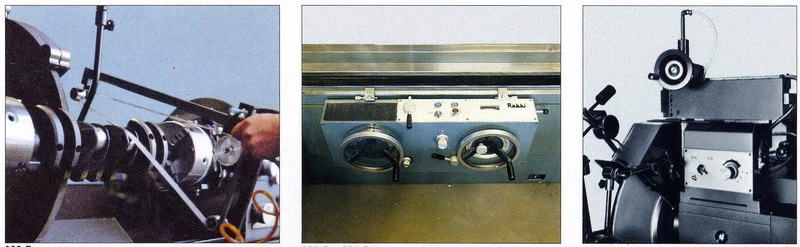

Steady rest, wheel periphery and side truing attachment and V-square for measuring the crankpins centerline distance

V-square with dial gauge for centering of crankpins, cooling installation with tank

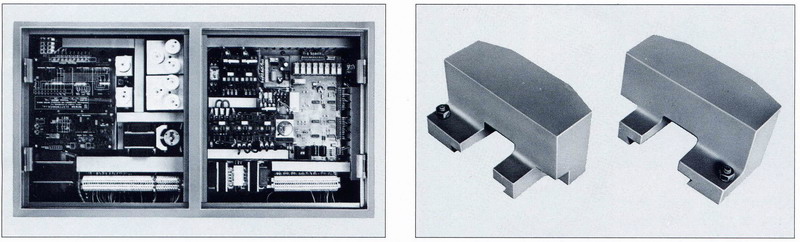

Electric cabinet and pair of additional counter weights

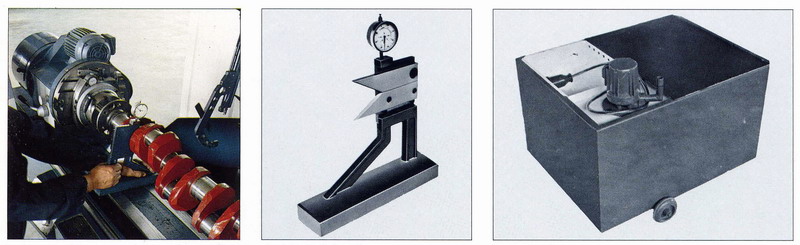

Systems for gauging while working, balancing stand for grinding wheels

Portable belt super finisher, infinitely variable hydraulic table traverse speed 0 to 3000 mm/min with automatic reversing and variable dwell for cylindrical grinding, hydraulic truing attachment

Eccentricity control device with dial gauge, truing fixture for checking concentricity

|