|

| |

Industrial - ROBBI:

Tube horizontal honing machines models LYOR

LYOR horizontal tube honing machines are manufactured in Italy by ROBBI S.p.A. The machines are designed for honing the bores of cylinders with diameters up to 500 mm and length up to 8000 mm.

LYOR machines have exceptional rigidity and power. The hydraulic cylinder controls the movement of the honing head. A three-phase electric motor controlled by a frequency inverter provides servo control by rotating the spindle. Transmission from the engine is carried out by a gearbox, all the mechanisms have a solid and rigid design, designed for high torque and removing large allowances.

Programming the operation is very easy with the touch screen. Visualization of all operating data allows the operator to intervene in the machine during the entire working cycle.

Each machine is designed to provide high accuracy and at the same time to be easy to use. Therefore, the machines are designed to meet the needs of the operator and are fast, simple and do not require special knowledge and skills. The final choice is easy: the machines are reliable, convenient and accurate; their prices are acceptable, which means a profitable return on investment. The operative communication with the manufacturer guarantees, if necessary, consultation and prompt delivery of the required spare parts and consumables.

Technical features of LYOR machines

ased on more than 60 years of experience in the manufacture of honing machines, ROBBI produces two versions of horizontal tube honing machines:

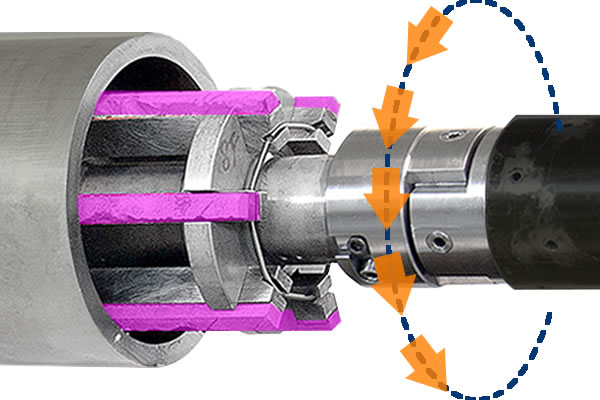

- LYOR-M version with one spindle. This is the basic version of the machine. The detail (tube) is clamped on prisms. The hydraulically expandable honing head rotates in a fixed part.

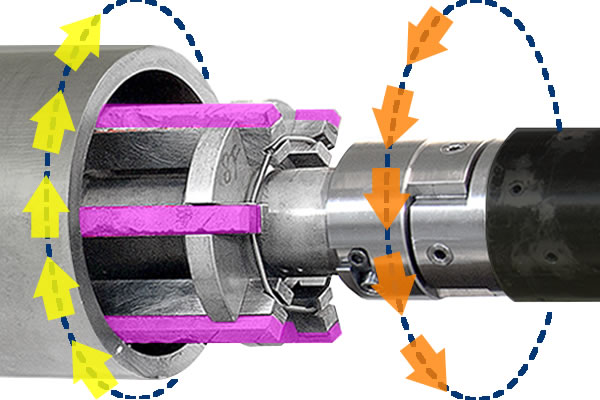

- LYOR-S version with two spindles. In addition to the honing head spindle with hydraulic extension of the honing stones, the second spindle rotates the part in the opposite direction to the honing head.

|

Lyor M – Basic Version

The tubes are clamped on prisms. The hydraulic expansion honing head rotates inside the component.

|

Lyor S – Version with 2 spindles

Besides the honing head spindle with the honing stone hydraulic expansion, a second spindle rotates the

component in the opposite direction to the honing head.

|

There are the benefits of having the contra-rotating component being worked against rotating with respect to the honer, including:

- improved roundness and straightness of the bore,

- major productivity, especially on small diameter components,

- the honing oil is distributed uniformly and constantly in the components, increasing the heat dispersion produced by the honing process. (on machines without rotation, the heat is concentrated on the top part of the component where there is less honing oil).

Both LYOR - M and S versions are equipped with a multifunctional touch screen control panel that provides easy programming and management of all operational parameters performed by PLC, including:

- end position of the honing head,

- the position of the honing head for loading / unloading the part,

- expansion pressure of honing stones (by request, the honing head expansion is controlled to a mechanical stop, with micrometric adjustment),

- speed of the longitudinal movement of the honing head,

- rotation speed of the honing head,

- spindle rotation speed of the work head (only for the LYOR-S model),

- quantity of honing strokes,

- quantity of finishing moves,

- honing stones pressure.

The touch screen of the control panel visualizes:

- set and alarm messages,

- all the parameters of the automatic cycle in operation,

- possible corrections made in the dialing parameters during the automatic work cycle.

|

Bed.

The bed is made of welded electric welding and normalized steel with oversized guides made of high-strength steel, the guides are covered by antifriction material.

|

|

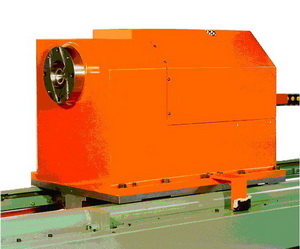

Work head.

Work head is made of welded electric welding and normalized steel, feed box has lubrication of gears by dipping, provides a connections at low speed, spindle motor has variable speed through a vector inverter.

|

|

Movable headstock for tube rotation (only for model S machine).

Movable headstock is welded of electric welding and normalized steel, with feed box having gear lubrication by dipping, providing connection at low speed, spindle motor with variable speed by means of a vector inverter, hydraulically controlled self-centering chuck (only for model S machine).

|

|

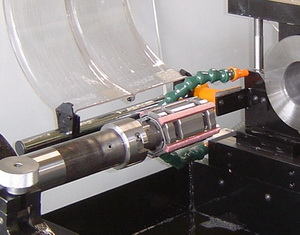

Honing heads.

Hydraulic expansion system for honing head stones with smooth regulation of stone pressure. The hydraulic station is designed as a separate unit from the machine. Cooling system with pump and reservoir with the possibility of using a cleaning system. Electrical and electronic components are enclosed in a control cabinet with CE safety protection. Pushbutton control panel and the PLC allow working in both automatic and manual modes.

|

|

The centering clamp for the traveled steady rest (only for the model S machine).

Provides clamping and strict centering of the tube and honing head.

|

TECNICAL SPECIFICATION Of LYOR M, S MACHINES

PARAMETERS / MODELS

|

40.20

|

40.30

|

40.40

|

40.50

|

40.60

|

40.70

|

|

Bore diameter (Min. – Max.)

|

mm

|

20 - 400

|

|

Max. tube length

|

mm

|

2000

|

3000

|

4000

|

5000

|

6000

|

7000

|

|

Max. honing head stroke

|

mm

|

3000

|

4000

|

5000

|

6000

|

7000

|

8000

|

|

Number of steady rests for honing head extension

|

-

|

1

|

2

|

|

Machine length

|

m

|

9

|

11

|

13

|

15

|

17

|

19

|

|

Machine width

|

m

|

2,8

|

3,4

|

STANDARD EQUIPMENT

- Pair of prism for tube clamping

- Self-centering chuck with hydraulic tube clamping

- 1 rest for honing head extension

- 1 travelling rest for honing head extension for machines with honing stroke major than 4 meters

- Service spanners

- Operating Manual.

EXTRA EQUIPMENT

- Self centering steady-rests with hydraulic self-centering clamp.

- Honing head expansion stroke controlled by a mechanical stroke end, with micrometric adjustment.

- Honing heads and stones.

- Honing head extensions.

- Magnetic cleaner, paper roll cleaner or combined magnetic and paper roll cleaner.

HYDRAULICALLY EXPENDABLE HONING HEADS

TYPE

|

TLY26

|

TLY30

|

TLY35

|

TLY45

|

TLY60

|

TLY80

|

TLY100

|

|

Honing diameter, mm

|

26-30

|

30-35

|

35-45

|

45-60

|

60-80

|

80-100

|

100-125

|

TYPE

|

TLY125

|

TLY150

|

TLY180

|

TLY220

|

TLY260

|

TLY300

|

|

Honing diameter, mm

|

125-150

|

150-180

|

180-220

|

220-260

|

260-300

|

300-400

|

|