|

|

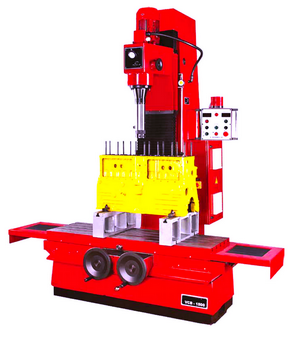

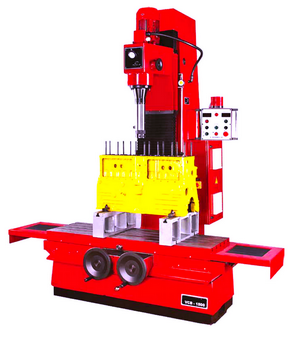

Automotive - DALCAN Machines-Denmark:

Cylinder boring machines models VCB (VCBM)

Inexpensive high precision machines for boring all types of cylinders and blocks, including cylinders of motorbikes, with possibility of surface machining. All the models have infinitely adjustable spindle speed and feed with frequency converters and a large set of tools for any parts machining.

M machine modifications have an infinitely variable table feed and possibility of installing a milling head. The color is red in standard, any other colors are optional.

Technical features

- Base, Cross Slide, Table, Column and boring slide (gear box) are of fine-graded, alloy casting.

- Stress relief after rough machine ensures rugged and vibration free operation of the machine.

- Boring slide setting with tapered gibs to avoid vibration and achieve better boring accuracy.

- Auto stop spindle rotation and rapid return of boring head after completion of boring operation.

- Anti-friction wear resistant lines provided on all sliding surfaces of the boring slide to minimize wear and tear.

Manual feeds operated by

pulse generator. Digital display for boring head movements, spindle speeds and table movements.

|

Easy & quick bore centering and machining positioning is possible within built dial indicator

|

In boring spindle, you can take up the tool setting micrometer, for advantage accurate repeatable tool setting.

|

TECHNICAL SPECIFICATION

| PARAMETERS/

MODELS |

VCB 1200 (VCBM 1200) |

VCB 1500 (VCBM 1500) |

VCBM 2200 |

VCBM 2500 |

|

Capacity

|

| Boring capacity with standard equipment |

mm |

62-135 |

48-220 |

62-265 |

62-265 |

| Boring capacity with extra spindle |

mm |

38-190 |

38-310 |

38-310 |

38-350 |

| Maximum boring head travel |

mm |

600 |

700 |

860 |

1100 |

| Milling length |

mm |

1250 |

1350 |

1800 |

2300 |

| Milling width |

|

350 |

350 |

400 |

400 |

| maximum distance head to table |

mm |

1300 |

1340 |

1500 |

1500 |

| Maximum distance from spindle

centre to column |

mm |

340 |

370 |

450 |

520 |

| Working table size (L x W) |

mm |

1200x400 |

1550x500 |

1800x600 |

3000x700 |

| Table traverse - longitudinal |

mm |

980 |

1530 |

1780 |

2530/2950 |

| Table traverse - cross wise |

mm |

80 |

130 |

180 |

230 |

| Max work piece on table |

kg |

750 |

750 |

1000 |

2500 |

|

Powers, speeds and feeds

|

| Spindle speeds |

rpm |

0-500 |

0-500 |

0-500 |

0-500 |

| Spindle feeds |

mm/rev |

0,09-0,18 |

0,05-0,25 |

0,05-0,25 |

0,05-0,25 |

| Table feeds |

mm/min |

- /40-80 |

- /40-80 |

0-150 |

0-150 |

| Spindle speed motor |

kW |

1,5 |

1,5 |

1,5 |

2,2 |

| Motor rapid & feed |

kW |

0,5 |

0,5 |

4,0 (servo) |

4,0 (servo) |

| Motor table traverse longitudinal |

kW |

0,37 |

0,37 |

0,37 |

0,37 |

|

Dimensions

|

| Length x width x height of the machine |

mm |

2200x1300x2440 |

2800x1420x2520 |

3300x1800x3050 |

4150x1800x3050 |

| Work space required (Lx W) |

mm |

2800x1700 |

4050x1520 |

4400x1850 |

4500x1850 |

| Net weight |

kg |

2500/2650 |

3000/3500 |

4800 |

5000 |

| Gross weight |

kg |

1850 |

2750 |

3850 |

4750 |

| Shipping volume |

m3 |

7,0 |

9,0 |

12,0 |

15 |

STANDARD EQUIPMENT*

- Setting up parallel 100mm.

- Setting up parallel 200mm.

- Setting up parallel 300mm.

- Boring spindle dia 46mm with centring device.

- Boring spindle dia 60mm with centring device

- Boring spindle dia 85mm with centring device.

- Boring spindle dia 125mm with centring device.

- Boring head dia 125 with centring device

- Boring head dia 175 with centring device

- Boring head dia 225 with centring device

- Boring tool dia 18 x 37mm long

- Boring tool dia 18 x 47mm long

- Boring tool dia 18 x 70mm long

- Boring tool dia 18 x 95mm long

- Chamfering tool 46mm long

- Chamfering tool 60mm long

- Chamfering tool 85mm long

- C' spanner for dia 85 spindle

- C' spanner for dia 125 spindle

- Head loosening rod.

- Tool setting micrometer assembly

- Tool setting micrometer fixing bracket & knob

- Allankey set (9nos)

- Table gib adjusting handle.

- Double end spanner 24/26

- Double end spanner 30/32

- T bolt washer with nut

- Block tightening clamp

- Milling spindle

- Milling tools inserter type

- Oil gun

- Levelling plate with bolt

- Foundation bolt washer & nut

- T handle allenkey 4mm

- T handle allenkey 5mm

- Lifting hole cover

- Depth setting device with dial

- Operation manual

*- depends from model of machine

Please, note - all needed boring spindles are included in standard equipment!

EXTRA EQUIPMENT

- Boring spindle dia 36mm

- Boring head dia 225mm

- Boring head dia 275mm

- Boring head dia 300mm

- Setting up parallel 100mm height

- Setting up parallel 130mm height

- Setting up parallel 200mm height

- Quick clamping fixture

- V type block clamping fixture adjustable

- Universal angle fixture (60* & 90*)

- Milling inserts

- Clamping Т-bolts with nuts

- Boring bits and inserts

- Tool grinder

|