Automotive - DALCAN Machines Denmark:

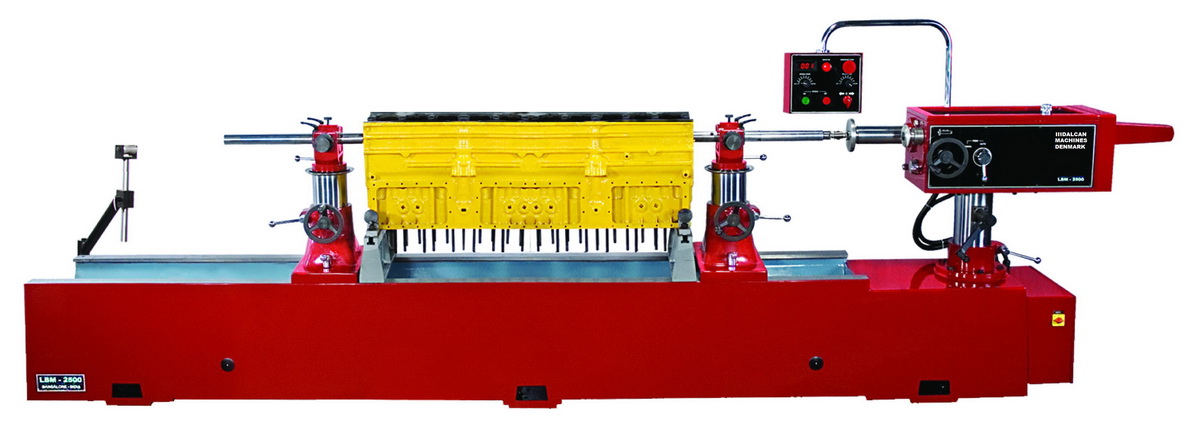

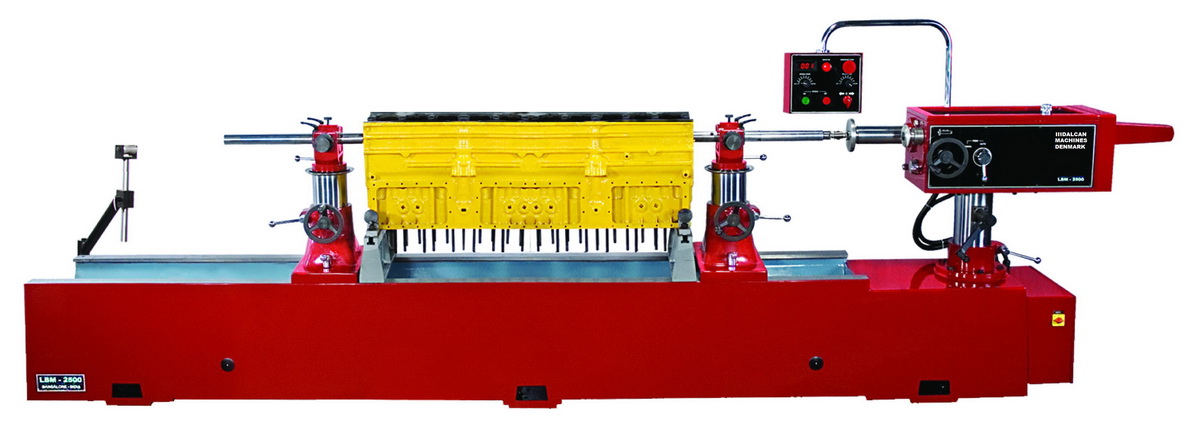

Line-boring machines models LBM

Simple, but very accurate, convenient and reliable machines for machining main bearings bores in engine blocks, as well as camshaft bearing bores in cylinder heads. Two models are produced, differing by the maximum permissible length of the cylinder blocks - LBM 1500 (1500 mm) and LBM 2500 (2500 mm). The coloring of the machines is in red, but any color can also be ordered at the customer's request.

TECHNICAL FEATURES:

Bed

Heavy bed is made of aged iron with stiffeners, eliminating the influence of vibrations on the machining accuracy.

Cylinder block Installation and adjustment

Centering of the part is made preliminary by means of cones, then the final centering is made with two universal centering devices with dial gauge. Special calipers ensure accurate alignment of the boring bar position with respect to the block surface. This guarantees the complete versatility of the machine for the repair of any bearings with a boring range from 24 to 225 mm.

Boring head

The boring head is mounted on a vertically adjustable support, which ensures a fast and accurate alignment of the spindle position with respect to the boring bar. Controls are grouped on a remote control on the boring head for the operator convenience. Spindle speed and feed have infinitely adjustment with reversal direction. Boring spindle has two stops and the possibility of using extension bars to increase of boring length. The boring head gear has automatic lubrication.

Boring bar bearings

The boring bar bearings are vertically adjusted, rotated and moved in all planes. Floating and adjustable boring bar bearings with the possibility of transverse movement allow quick adjustment of the block position.

|

|

| Tool setting micrometer device with magnetic base, for tool setting accurate repeatability. |

Centering of boring bar on the machine is done very quickly with the dial indicator. |

TECHNICAL SPECIFICATIONS:

| Parameters |

LBM 1500 |

LBM 2500 |

| Maximum length of block |

mm |

1500 |

2500 |

| Min. distance between top of bed and boring bar center |

mm |

450 |

550 |

| Max. distance between top o1 bed lo boring bar center |

mm |

750 |

850 |

| Boring capacity with standard equipments |

mm |

32-140 |

32-175 |

| Boring capacity with optional equipments |

mm |

25-225 |

24-225 |

| Spindle speed infinitely variable |

rpm |

80 - 700 |

80 - 700 |

| Feed both directions infinitely variable |

mm/min |

0-50 |

0-50 |

| Max. travel of boring bar |

mm |

450 |

450 |

| Drive motor( A. C) |

kW |

1,5 |

1,5 |

| Spindle feed motor (D.C.) |

kW |

0,18 |

0,18 |

| Dimensions |

| Length of machine |

mm |

3840 |

4840 |

| Width of machine |

mm |

750 |

750 |

| Height of machine |

mm |

1750 |

1850 |

| Work space required (L x W x H) |

mm |

6000x1750 X 2000 |

5000 X 1750 X 1900 mm |

| Net weight (approx.) |

kg |

1750 |

2250 |

| Gross weight (approx.) |

kg |

2250 |

2750 |

| Shipping volume |

m3 |

6 |

8 |

| Packing case outer size (L x W x H) |

mm |

4100 x 1000x1495 |

5100 X 1000 X1595 |

Standard equipment:

- Setting up parallel100mm height x 550mm long

- Setting up parallel100mm height x 750mm long*

- Setting up parallel 200mm height x 550mm long

- Boring bar dia 30 x 1600mm long

- Boring bar dia 48 x 2000mm long

- Boring bar dia 60 x 3000mm long*

- Bearing bush tor boring bar dia 30mm

- Bearing bush tor boring bar dia 48mm

- Bearing bush for boring bar dia 60mm*

- Extra support for boring bar dia 60mm with bush*

- Centering cone dia 30

- Centering cone dia 48

- Centering cone dia 60*

- Cutter head dia 90 for boring bar dia 48mm

- Cutter head dia 100 for boring bar dia 60mm*

- Cutter head dia 135 for boring bar dia 60mm*

- Boring tool dia 7 x 22mm long

- Boring tool dla 7 x 28mm long

- Boring tool dia 12 x 55mm long

- Boring tool dia 12 x 67mm long

- Boring tool dia 12 x 20mm long*

- Boring tool dia 12 x 30mm long*

- Boring tool dia 12 x 35mm long*

- Facing tool dia 12 x 69mm long

- Tool setting micrometer

- Magnetic base small

- Magnetic base big*

- Centering device with dial indicator

- Boring bar rest

- Block clamping assembly

- Leveling plate with bolt

- Foundation bolt with nut

- Oil gun

- Alien key set (9nos)

- Double end spanner 24126

- Handle type alien key 4mm

- Handle type alien key 6mm

- Centering pin dia 7 & 12mm

- Operation manual

*- for LBM2500 model only

NOTE - standard equipment includes all needed tools for working!

Extra equipment:

- Boring bar dia 22 X 1200 mm

- Boring bar dia 30 x 1600 mm

- Boring bar dia 40 x 2000 mm

- Boring bar dia 48 x 2000 mm

- Bearing bush dia 22 mm

- Bearing bush dia 40 mm

- Centering cone dia 22 mm

- Centering cone dia 40 mm

|